Custom Nutraceutical Tablet Manufacturers

Deliver variety of certified Tablets packed in high quality packaging material and accurate composition

Dedicated To Quality Custom Manufacturing

We choose high-quality ingredients for your formula and must do post-encapsulation inspection. All is done at the most affordable costs. We have experts to assist you in developing a new product for your target market or discussing how to scale your manufacturing properly. It is our responsibility as your partner to ensure long-term success.

TABLETS

Tablets are one of the most common dosage forms with diverse options and blends.

Being one of the top nutraceutical tablet manufacturers, we can produce your private label tablet supplement to the highest standard.

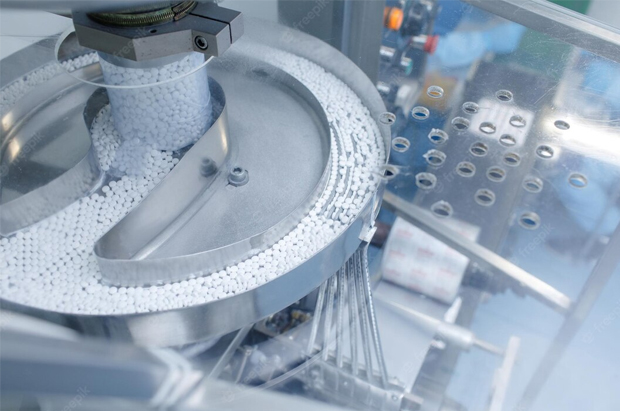

Tablet Manufacturing Process

The basic processes in tablet manufacturing, including weighing, milling and mixing are same, but the subsequent steps differ according to the method used to prepare the tablets. There are three basic methods for making tablets.

Wet Granulation Tablet Manufacturing Process

It is the most popular and commonly utilised technique. This method entails a number of phases, including component weighing, mixing, granulation, and screening of damp pass, as well as drying, lubrication, and compression of tablets.

The main active component, diluent, and disintegrant are all combined together before being passed through the sieve. To avoid overwetting of the tablet, the amount of binding agent applied should be sufficient. If the powder is not properly wetted, the granules become too soft and can be broken down during lubrication, which makes tablet compression problematic.

Dry Granulation Tablet Manufacturing Process

If the tablet ingredients are particularly sensitive to moisture or cannot withstand high temperatures during drying, slugging may be utilised to create the granules. Dry granulation, also known as twofold compression, removes a number of stages, including slugging of the powder mass.

To make the slug, the active component, diluent, and lubricant are mixed together. As a result, the compressed slug passes through the mesh or mill, and the residual lubricant is added to the granulation, appropriately blended, and crushed to create the tablets.

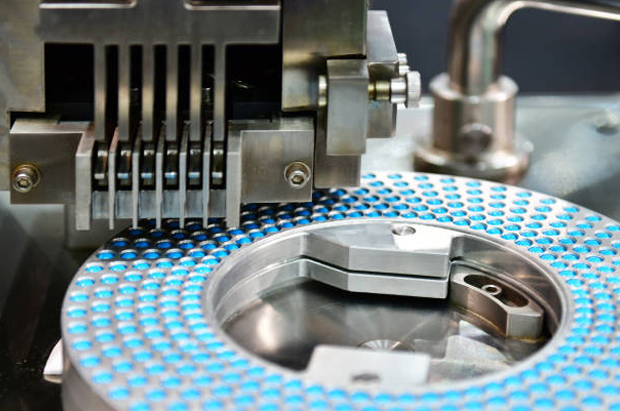

Direct Compression Tablet Manufacturing Process

The powdered substance is compressed directly into tablets via direct compression. If the medicine makes up a significant fraction of the tablet’s overall weight [86-90], direct compression is used.

Tablets containing a suitable diluent that acts as a carrier or vehicle for the drug can be manufactured with a concentration of drug components of 25% or less. The tablets produced using the aforesaid approach are compressed using a single or multiple station compression machine.

Effervescent Tablets

Solid dosage form, readily dispersed in a glass of water before being administered.

For nutritional supplements and medications, effervescent technology offers a novel dose form. Patients who have difficulty swallowing tablets or capsules will benefit from this product.

Compressed Tablets

In the nutritional supplement sector, compressed pills are perhaps the most frequent.

These tablets are designed to be ingested whole, with no chewing or breaking down. It is made by putting dry granular granules under enough pressure to make them stick together.

Fast Melt Tablets

Orally disintegrating tablet excipient system that is ready to use.

These are tablets that dissolve quickly in the mouth without the use of water, and they’re also good for soft chewable tablets. It can be used to make immediately compressible ODTs by combining active pharmaceutical ingredients (APIs) and lubricants together.

Chewable Tablets

Oral medication with ease of swallowing and without the use of water.

Chewable tablets are meant to be chewed and then ingested by the patient instead of being swallowed whole. They should be appealing to the taste buds and easy to chew and swallow.

Get The Manufacturing Cost Estimate

Fill out our “request a quote” form and we’ll send you a custom price quote so you can start making your nutraceutical supplements.

call us at 9289609972 , 9899821966 , 9289609970 for more information

Why Choose Us as Your Tablet Manufacturers?

Selecting the right Tablet Manufacturers for your nutraceutical business is crucial for ensuring high-quality tablet production, regulatory compliance, and market competitiveness. As one of the leading tablet manufacturers in India, we specialize in producing premium nutraceutical tablets, dietary supplements, and health products in various forms. Our advanced tablet manufacturing facility ensures consistent quality, whether you need effervescent tablets, chewable tablets, fast melt tablets, or compressed tablets. With cutting-edge technology and strict quality assurance, we guarantee that your nutritional tablet supplements meet industry standards while offering excellent shelf life and consumer appeal.

Advanced Quality Control in Tablet Manufacturing

As top-rated Tablet Manufacturers, we follow stringent tablet manufacturing protocols to ensure product efficacy and safety. Our nutraceutical tablet production process includes raw material testing, in-process quality checks, and finished product evaluations. Our GMP-certified tablet manufacturing facility adheres to ISO 9001:2015 and HACCP guidelines, ensuring each batch of nutritional tablets is free from contaminants and meets label claims. Whether you require herbal tablets, vitamin tablets, protein tablets, or pharmaceutical-grade tablets, our in-house quality control team ensures unmatched consistency in tablet formulation and manufacturing.

Custom Formulations by Leading Tablet Manufacturers

Our expertise in custom tablet manufacturing allows us to create unique formulas for private label tablet supplements. As experienced tablet manufacturers in India, we work closely with brands to develop personalized nutraceutical tablet formulations tailored to specific health concerns. From multivitamin tablets and sports nutrition tablets to herbal supplements and immunity-boosting tablets, we provide complete R&D support. Our contract tablet manufacturing services help businesses expand their product line with superior dietary supplement tablets made from the finest ingredients and cutting-edge tablet compression technology.

Scalable Production and Fast Turnaround Times

As one of the most efficient Tablet Manufacturers, we ensure rapid production, flexible batch sizes, and competitive pricing. Our high-capacity tablet manufacturing facility produces millions of tablets monthly, meeting the demands of both small businesses and large-scale supplement brands. With streamlined nutraceutical tablet production, stocked raw materials, and high-speed tablet compression machinery, we guarantee industry-leading turnaround times. Whether you need organic tablets, weight management tablets, or functional food supplements, our tablet manufacturing company ensures timely delivery, cost-effectiveness, and high consumer satisfaction.